Mesin Pemoles Serat Optik: Solusi Efisien yang Mendukung Perlengkapan Kustom dan Berbagai Granularitas Film Pemoles

Dalam industri komunikasi serat optik, kualitas pemrosesan dan pemolesan ujung serat optik secara langsung memengaruhi stabilitas transmisi sinyal dan pengurangan kerugian. Sebagai peralatan inti, Mesin Pemoles Serat Optik (Mesin Pemoles Serat Optik) bertanggung jawab untuk memoles ujung konektor serat optik hingga hasil akhir yang halus, bebas goresan, dan kerugian rendah. Seiring dengan terus berkembangnya aplikasi serat optik, pengguna memiliki persyaratan proses yang bervariasi dan tuntutan produksi massal, yang membuat fleksibilitas dan kemampuan kustomisasi peralatan menjadi sangat penting. Artikel ini akan berfokus pada keunggulan Mesin Pemoles Serat Optik dalam mendukung perlengkapan kustom dan menawarkan berbagai ukuran grit film pemoles, membantu perusahaan mencapai keseimbangan optimal antara efisiensi produksi dan kualitas.

1. Dukungan Fleksibel untuk Perlengkapan Kustom

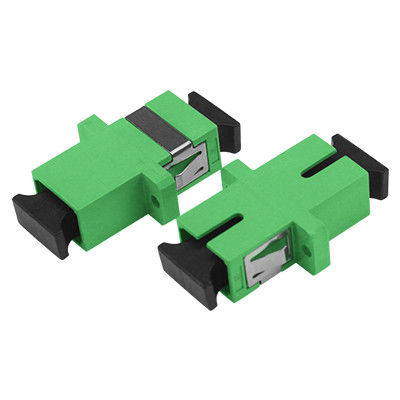

Terdapat banyak jenis konektor serat optik, seperti SC, LC, FC, ST, MPO, dan E2000. Ini sangat berbeda dalam dimensi dan struktur ujungnya, yang memerlukan perlengkapan khusus untuk pemolesan. Peralatan tradisional sering kali hanya mendukung sejumlah model utama tertentu, yang mengharuskan perusahaan mengganti peralatan atau melakukan penyesuaian yang rumit saat memproduksi beberapa model, sehingga meningkatkan biaya produksi.

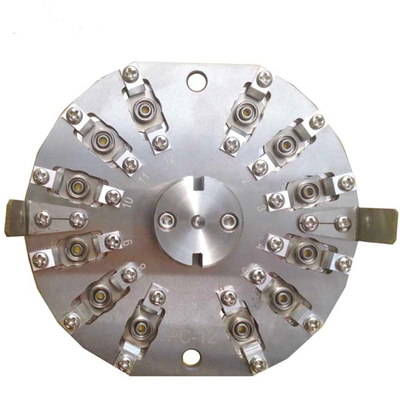

Desain Mesin Pemoles Serat Optik mengatasi masalah ini dan menawarkan layanan perlengkapan yang disesuaikan:

- Kompatibilitas Multi-Antarmuka: Perlengkapan khusus dapat disesuaikan untuk mengakomodasi antarmuka yang berbeda, memungkinkan banyak penggunaan dengan satu mesin dan mengurangi investasi peralatan.

- Presisi Terjamin: Pemesinan CNC presisi tinggi memastikan penempatan serat yang stabil selama pemolesan, secara efektif mencegah eksentrisitas dan ketidakrataan ujung.

- Penggantian Cepat: Desain perlengkapan modular memungkinkan operator mengganti perlengkapan dalam hitungan menit, secara signifikan meningkatkan fleksibilitas produksi.

- Kustomisasi Massal: Untuk produksi skala besar, produsen dapat menyesuaikan perlengkapan multi-stasiun berdasarkan karakteristik spesifik lini produksi mereka, memungkinkan pemolesan simultan beberapa serat dan meningkatkan kapasitas produksi.

Perlengkapan khusus tidak hanya mengatasi masalah kompatibilitas tetapi juga membantu perusahaan mencapai keseimbangan antara "batch kecil dengan beberapa model" dan "batch besar dengan satu model," yang secara signifikan meningkatkan pemanfaatan peralatan.

2. Beberapa Pilihan Granularitas Film Pemoles

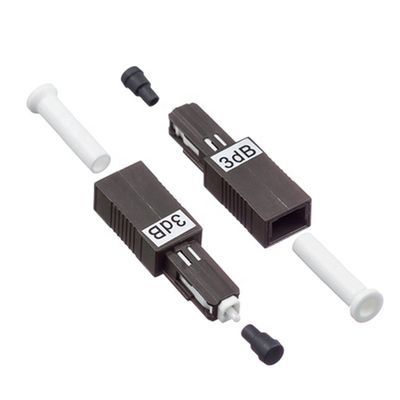

Selama pemrosesan ujung serat, pilihan ukuran grit film pemoles sangat penting. Film berbutir kasar digunakan untuk penyelesaian awal, menghilangkan ketidakteraturan dan goresan ujung; film berbutir halus digunakan untuk pemolesan halus dan pemolesan akhir, memastikan ujung serat mencapai kinerja optik yang ideal.

Mesin Pemoles Serat Optik mendukung kombinasi fleksibel dari film pemoles dengan berbagai ukuran grit:

- Film berbutir kasar (30μm, 15μm): Digunakan pada tahap awal untuk memangkas ujung serat dengan cepat dan menghilangkan gerinda dan retakan yang disebabkan oleh pemotongan.

- Film berbutir sedang (9μm, 6μm, 3μm): Secara bertahap memperbaiki ujung, mengurangi goresan permukaan, dan memastikan kehalusan.

- Film berbutir halus (1μm, 0,5μm, 0,3μm): Mencapai pemolesan cermin presisi tinggi, memastikan ujung yang halus dan bebas cacat yang memenuhi persyaratan kerugian penyisipan rendah dan kerugian balik tinggi.

Proses multi-tahap ini tidak hanya memastikan kualitas ujung serat tetapi juga memperpanjang umur film pemoles. Operator dapat secara fleksibel menyesuaikan langkah-langkah pemolesan dan kombinasi grit film berdasarkan standar produk yang berbeda (seperti ujung PC, UPC, dan APC) untuk mencapai keseimbangan optimal antara efektivitas biaya dan kualitas.

III. Nilai Aplikasi dan Prospek Industri

Dengan pesatnya perkembangan industri seperti 5G, FTTx, pusat data, dan penginderaan optik, permintaan akan kualitas konektor serat optik dan kapasitas produksi menjadi semakin ketat. Mesin Pemoles Serat Optik, dengan perlengkapan yang dapat disesuaikan secara fleksibel dan berbagai ukuran grit film pemoles, tidak hanya memenuhi kebutuhan produksi dari berbagai skenario tetapi juga memberikan perusahaan hasil yang lebih tinggi dan biaya pengoperasian dan pemeliharaan yang lebih rendah.

Di masa mendatang, dengan diperkenalkannya teknologi otomatisasi dan cerdas, mesin pemoles serat optik akan lebih lanjut mengintegrasikan deteksi AI dan analisis data besar untuk mencapai pemantauan kualitas ujung secara real-time dan pemeliharaan prediktif, membantu perusahaan mendapatkan keuntungan di pasar yang sangat kompetitif.

Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!  Pesan Anda harus antara 20-3.000 karakter!

Pesan Anda harus antara 20-3.000 karakter! Silakan periksa email Anda!

Silakan periksa email Anda!